This issue faces many in the field and may only be understood once it happens to them. To prevent such an issue, I want to inform you of various practices to protect your 3D filament from moisture.

In 3D printing, a crucial aspect often overlooked is the hygroscopic nature of FDM (Fused Deposition Modeling) in 3D printing filaments – a fancy term indicating their ability to absorb moisture in the surrounding air. While this characteristic might seem harmless, it can pose a significant challenge during the printing process, leading to many failed prints and clumping of the filament not adhering to the bed.

The science behind it lies in the composition of these filaments. Constructed from plastic polymers, they consist of interconnected chains of molecules. When exposed to moisture, these water molecules infiltrate the filament, breaking apart these chains and consequently compromising the integrity of the plastic, also known as hydrolysis.

The result? A host of printing predicaments. Before panic sets in, it's important to note that not all is lost when dealing with "wet" filament spools. With the right approach, these filaments can be salvaged. Moreover, a proactive strategy for storage can hinder future moisture-related mishaps.

This article aims to demystify the intricacies of handling moisture in 3D printing filaments. We will delve into identifying wet filament methods for effectively drying it and conclude with insights into maintaining a moisture-free storage environment.

Noticing Your Filament Becoming Wet

For example, look at the different roles of filaments such as PLA, ABS, and PETG. The moisture absorption rates are different for each filament and can vary significantly. However, some indicators signal the presence of a moisture-laden spool. Keep an eye out for the following signs:

1. Popping or cracking sounds during extrusion

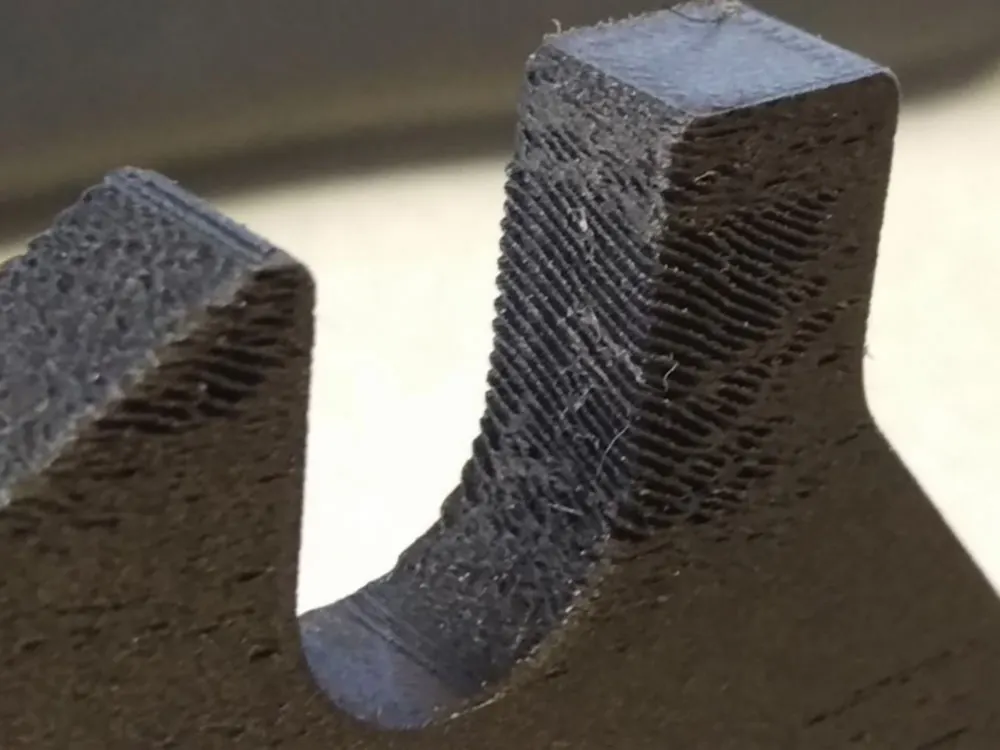

2. Markedly reduced part strength and layer adhesion

3. Uneven extrusion lines

4. Excessive stringing, blabbing, or oozing

5. Abnormally textured or "fuzzy" surfaces on prints

If you've observed any of these signs, it's advisable to address the issue quickly by drying your filament. Materials like nylon, PETG, PVA, and flexibles, known for their high hygroscopicity, can start causing problems after just one night of exposure to open air.

Dry storage solutions can prevent such complications, a topic we'll explore shortly. However, swift action is essential to preserve print strength, and the quality of your filament has already succumbed to moisture.

Fortunately, there are several safe methods to dry your filament effectively. These approaches vary in cost and complexity. Let's delve into the primary techniques for restoring your filament to a dry state and explore strategies to maintain its dryness moving forward.

Approach #1: Drying Filaments

A convenient solution for handling the moisture issue in 3D printing filaments is available for purchase. Dedicated devices designed exclusively for drying filament have emerged as a reliable option, particularly for enthusiasts seeking specialized features.

These filament dryers come in various types, each offering distinct features while maintaining user-friendly operation. The process is straightforward:

Place your spool (or spools) inside the dryer.

Select the desired setting.

Let the device work magic in removing the moisture from your filaments in a few hours.

Typically, these dryers need a power source and employ a heating element to establish a warm environment. The heat effectively evaporates moisture from both the filament and the surrounding air. Users can usually choose from a range of temperatures based on the filament type and set a timer to control the drying duration.

Once the timer concludes, your spool will not be completely free of moisture but will have substantial improvements in its integrity. Some dryers even come equipped with a filament feeder that synchronizes with the printer, allowing simultaneous drying and printing to save time and effort to maintain the print.

Notable names of heated filament dryers, such as the Sovol SH01 and the Sunlu FilaDryer S2, offer heightened reliability and precision in the drying process. Investing in these machines ensures a worry-free experience, allowing users to shift their focus from filament issues to fine-tuning their printers for impeccable prints.

Filament Drying: A Do It Yourself Option

As you delve into the topic of 3D printing and devise your build plan, it's crucial to understand the fundamental materials that form the backbone of any effective dryer or dry box setup. These essential components ensure optimal conditions for your Filament:

1. Storage Method: Typically, this is a transparent, airtight plastic box, enclosure, or vacuum-sealable bag. Ensure its size accommodates at least one spool, consider the dimensions of your filament spools, and factor in how many you intend to store and the available space.

2. Spool Mount: This element secures your spools for uniform drying. It can manifest as rollers, rods, or a custom 3D-printed fixture. Depending on your chosen storage container, a mount may be optional, especially in round containers.

3. Drying Element: Choose between an active or passive drying approach. Active methods involve a heat source like a heating fan or a food dehydrator. Passive methods employ desiccants such as silica gel, salt, or molecular sieves.

When wanting to construct a basic dry box, off-the-shelf components are sufficient. However, for those aiming for a customized design, several optional components can elevate your box's functionality:

- Tools for Modifications: Tools to cut holes in the box are essential depending on your design. This can range from a power drill to a utility knife, ensuring precision without compromising the plastic.

- Tubing: PTFE tubes are ideal if you feed filament directly from the box to your printer. Threaded into the box's hole or through an adapter, these tubes maintain an airtight seal and protect the filament from external conditions.

- 3D Printable Parts: For those with a creative flair, designing custom parts like a spool mount or box-to-Bowden adapter can enhance the overall functionality of your box.

- Sensors: To monitor internal conditions, consider incorporating sensors that measure humidity, temperature, or both.

As you assemble your 3D printing toolkit, understanding and selecting these components will be pivotal in ensuring a smooth and practical printing experience.

Unlocking Creativity: Enhance Your Filament Drying Experience

Among the featured builds, several stand out, while classic dry box projects have garnered attention within the community:

1. Modern Hobbyist's Simple Box with Silica Beads: A straightforward solution incorporating silica beads for effective moisture control.

2. Becky Stern's Four-Spool DIY Dry Box: A versatile project designed to accommodate multiple spools, showcasing creativity in function and form.

3. Thomas Sanladerer's Spool-Winding Storage Solution: An innovative approach to spool organization, addressing the practical aspect of filament management.

4. Anybox Designs from Anybot: Highlighting various designs under the 'Anybox' umbrella, offering diverse solutions for filament storage.

While featured builds offer valuable insights, other notable projects include:

5. Tinkerman's Modded Food Dehydrator: An inventive modification for active drying, adding a unique touch to the food dehydrator concept.

While active drying projects are less common in the DIY sphere, examples like Tinkerman's illustrate the ingenuity within the community. These projects validate the DIY approach's effectiveness and encourage enthusiasts to explore and customize their filament drying solutions.

Approach #2: The Oven

It is not recommended due to safety concerns to use your regular everyday oven. If you must resort to this method, find a small portable oven that will be used primarily to reduce the chances of cross-contamination from filament to food for consumption during the drying process.

One of the most straightforward methods to dry filament involves a common household appliance: the oven. By carefully setting the temperature just below the glass transition point of the plastic, you can effectively eliminate moisture over four to six hours, with extended durations resulting in even drier filaments.

What is the Glass Transition Temperature in 3d printing?

The glass transition temperature (Tg) denotes the point at which a material transitions from a rigid, crystalline state to a glassy amorphous state. Simply put, it is the temperature at which a solid transforms its inherent physical characteristics from those resembling a rigid, crystalline structure to those characteristic of an amorphous solid in a rubbery state.

Here are some recommended temperature ranges for drying standard filaments:

- PLA: 50-55 °C = 122.00 * F - 131.00 *F

-PLA (Tg) is around 60 *C = 140.00 *F.

-PETG : 60 -65 C = 140.00 *F - 149.00 *F

-PETG (Tg) is around 85 *C = 185 *F.

- ABS: ~90-95 °C = 194.00 *F -203 *F

-ABS (Tg) is around 105 *C or 221 *F

- Nylon: ~ 70-75 °C = 158.00 *F - 167.00 *F

-Nylon (Tg) is around 80 C = 176.00 *F

However, patience is vital. Always wait for the oven to reach the target temperature before placing the spool inside. Ovens tend to overshoot during heating, and prematurely introducing the spool may lead to a molten mishap. Consider using an oven thermometer to monitor the temperature accurately. Deviating too far from the target temperature risks melting the plastic and fusing the entire spool.

Also, remember that certain 3D printing materials, especially ABS, can produce unpleasant odors and fumes during drying. ABS produces toxic fumes and must have the proper ventilation before use. Again, this raises considerations about using an appliance for food preparation. Exercise caution with non-food items in your oven, and ensure adequate ventilation after the filament drying process is complete. Being mindful of these details provides a successful filament drying experience without compromising your equipment or culinary space.

Approach #3: Food Dehydrator

The first method of drying your filament can be found in an unexpected place: the food dehydrator. Initially crafted for preserving foods like fruits and meats, these appliances offer an excellent alternative, especially for those lacking a suitable oven. Even though food dehydrators operate at lower temperatures than ovens, they provide enhanced temperature stability within the desired range, with the bonus of a convenient round shape, ideal for accommodating filament spools.

Similar to using an oven, the goal with a food dehydrator is to maintain a temperature slightly below the glass transition point of the material being dried. Typical food dehydrators operate within a temperature spectrum of 85 to 160 degrees Fahrenheit, although certain specialized models allow settings as low as 20 degrees Fahrenheit. In contrast, the majority of ovens have a minimum temperature range of 150 to 200 degrees Fahrenheit, rendering them too high for the gentle drying of numerous food items.

The values would be the same as before:

- PLA: 50-55 °C = 122.00 * F - 131.00 *F

-PLA (Tg) is around 60 *C = 140.00 *F.

-PETG : 60 -65 C = 140.00 *F - 149.00 *F

-PETG (Tg) is around 85 *C = 185 *F.

Temperature too high for a food dehydrator to achieve:

- ABS: ~90-95 °C = 194.00 *F -203 *F

-ABS (Tg) is around 105 *C or 221 *F

- Nylon: ~ 70-75 °C = 158.00 *F - 167.00 *F

-Nylon (Tg) is around 80 C = 176.00 *F

These affordable dehydrators are readily available online, often featuring removable layers and meshing that can be adjusted to fit various spool sizes. Additionally, customization is possible through 3D-printed attachments, enabling direct printing from a dehydrator.

Whether you're a seasoned 3D printing enthusiast or a newcomer to the craft, the food dehydrator emerges as a cost-effective and versatile solution for keeping your filament moisture-free, ensuring optimal printing results.

Proper Storage

After successfully drying your filament, the next step is maintaining its dryness over the long haul. Achieving this involves storing your dry spools in a humidity-controlled environment. Options range from a simple airtight box with desiccant packs to more sophisticated commercial solutions, with the former often proving sufficient. However, custom-designed dry boxes provide additional advantages.

Take, for instance, the Polymaker PolyBox, an innovative solution that directly feeds your printer and displays internal temperature and humidity levels. This built-in feature allows you to effortlessly monitor the dryness of your filament without any manual intervention.

It's crucial to note that while a practical storage solution can prevent further moisture absorption, it cannot reverse the drying process. If your Filament reencounters moisture or wasn't adequately dried initially, you'll need to employ one of the drying methods discussed earlier to restore its condition. By understanding and implementing proper storage practices, 3D printing enthusiasts can prolong the life and quality of their filaments, ensuring consistently successful printing endeavors.

Keywords: 3D Printing Moisture Damage Filament

Comentarios